Speficications

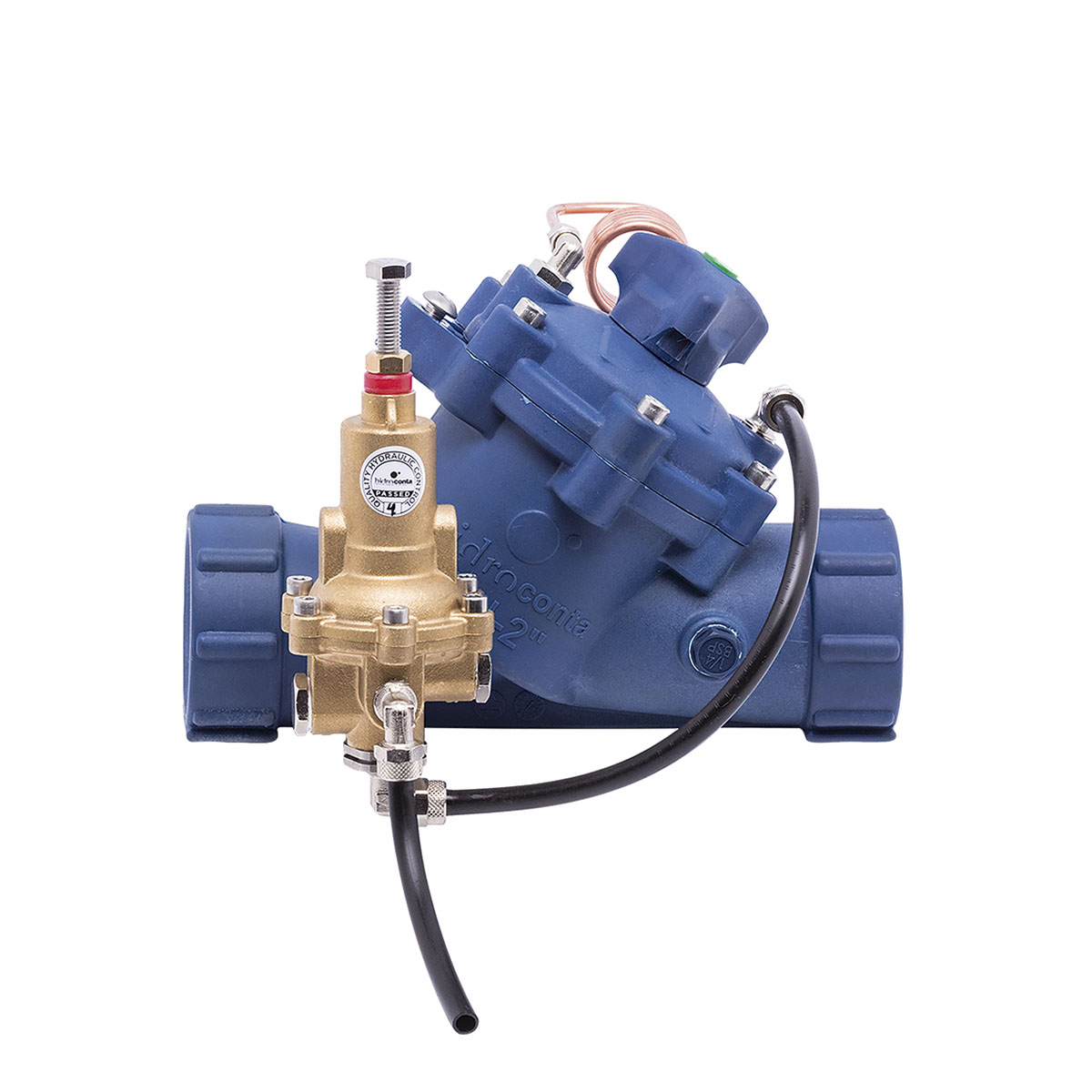

Hydraulic membrane or diaphragm valve.

- Hidroconta’s Taurus valve is designed with a Y-shape for a high flow rate capacity, maintaining very low pressure losses. The operation of the Taurus hydraulic valve is based on the use of the circulating fluid’s energy, opening and closing the membrane with the pressure injected by the water into the valve’s body chamber.

Built-in manual valve.

- The Taurus hydraulic valve is built into the body, featuring a manual valve to open and close it directly, with no need for additional accessories, such as three-way valves.

Low load losses and high KV.

- The body of the Taurus valve is manufactured in glass fibre reinforced polyamide, with very low load losses, since this is a free-flow valve with no obstacles, also eliminating the possible effects of pressure surges caused in the pipe.

Made out of plastic

- Taurus is a very light unit, since it is manufactured in glass fibre reinforced polyamide, including its built-in manual valve. In addition, the pilot lights provide additional functions and these can also be manufactured in this material.

Opened at very low pressures.

- Due to the hydrodynamic design of the valve body, the Taurus valve operates at a very low pressure, so it can regulate very low flow rates with a high accuracy.

Multipurpose

- Membrane valves are required in any water installation, since these are multipurpose elements. Taurus valves can be configured upon the customer’s request as a pressure reduction, flow limiter, quick pressure relief or flow rate accelerator valve, in addition to allowing other adjustment and multipurpose options.

FAQ

1- Why does not the valve open?

There may be insufficient pressure at the inlet pressure valve, you should examine the insulation valves of the system upstream and downstream, if they are closed open to allow the passage of water and generate pressure.

Another reason may be that the solenoid is calcified, clean it and replace parts as necessary.

2- Why does not the valve regulate at the desired control point?

It may be caused by the pilot because it is not adjusted properly, check it by tightening and loosening the screwdriver to see if there is a pilot reaction, so you can adjust the pilot to the desired opening and closing speed.

Check if the upstream filter is clogged and causes insufficient pressure to reach the pilot to activate the valve at the desired control point.

3- Why does not the valve close?

It may be that the filter is clogged, to check it, disconnect the copper line from the lid to see if there is water flow in the inlet. In this case clean the filter mesh.

If the main valve membrane fails, it can also give this result, replace the membrane for repair.

Another reason may be that the solenoid is calcified, clean it and replace parts as necessary.

4- Why does the membrane leak water?

It is usually produced by the accumulation of dirt between the membrane and its closing support, closing the valve manually, if the problem persists open the valve to clean the area.