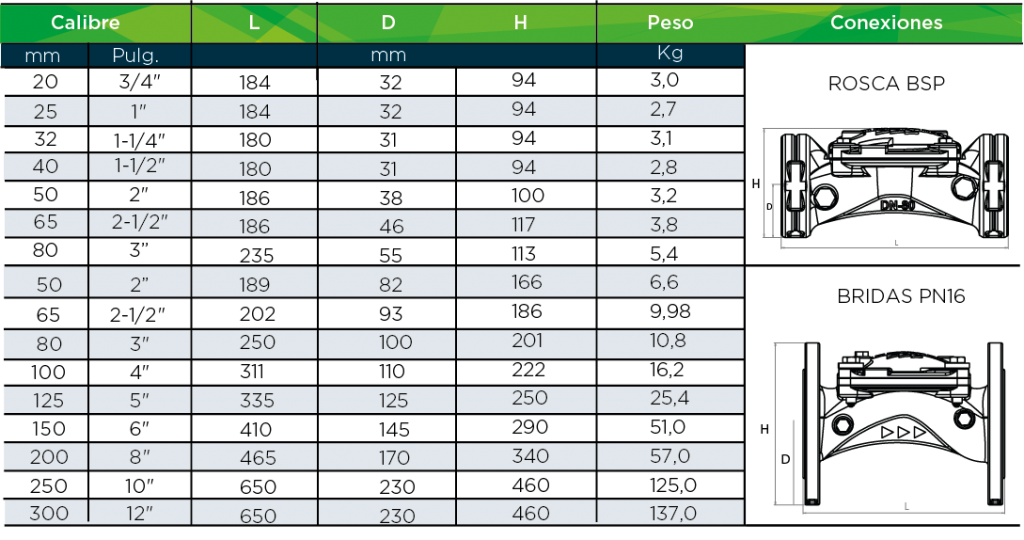

Specifications

Applications

The combined reducing and sustaining valve performs both functions independently. Prevents on-site generation:

- Pressure drops.

- Overpressures.

It is mainly used to automatically reduce downstream pressure in the distribution network and hold a minimum of pressure in the main high pressure line regardless of the demand for distribution.

Functioning

The reducing pilot acts on the valve so that it has a modulating function, in order to keep the downstream pressure constant for the set control value, the holding pilot acts on the valve so that it has a modulating function, in order to maintain the upstream pressure above the minimum control value. The reducer pilot must be adjusted regarding the installation needs.

Turning the reducer pilot screw clockwise you will reduce the outlet pressure. Turing the pilot anti-clockwise you will increase the outlet pressure.

Turning the sustainer pilot screw clockwise you will reduce the intlet pressure. Turing the pilot anti-clockwise you will increase the outlet pressure. Take into account the following aspects:

- Maximum reduction ratio: inlet pressure x 1/3. For example, with a 6 bar inlet pressure the outlet pressure will be 2 bar. Working in pressure under 2 bar the valve will suffer cavitation complications.

- Standard working rate as sustained valve: from 1 bar to 6.5 bar.

- Precision Ratio: preset pressure ± 0.3 bar.

FAQ

1- Why does not the valve open?

There may be insufficient pressure at the inlet pressure valve, you should examine the insulation valves of the system upstream and downstream, if they are closed open to allow the passage of water and generate pressure.

Another reason may be that the solenoid is calcified, clean it and replace parts as necessary.

2- Why does not the valve regulate at the desired control point?

It may be caused by the pilot because it is not adjusted properly, check it by tightening and loosening the screwdriver to see if there is a pilot reaction, so you can adjust the pilot to the desired opening and closing speed.

Check if the upstream filter is clogged and causes insufficient pressure to reach the pilot to activate the valve at the desired control point.

3- Why does not the valve close?

It may be that the filter is clogged, to check it, disconnect the copper line from the lid to see if there is water flow in the inlet. In this case clean the filter mesh.

If the main valve membrane fails, it can also give this result, replace the membrane for repair.

Another reason may be that the solenoid is calcified, clean it and replace parts as necessary.

4- Why does the membrane leak water?

It is usually produced by the accumulation of dirt between the membrane and its closing support, closing the valve manually, if the problem persists open the valve to clean the area.