LEOPARD pressure sustaining hydraulic diaphragm valve. Used in installations where a specific pressure should be sustained.

Leopard Pressure sustaining hydraulic valve

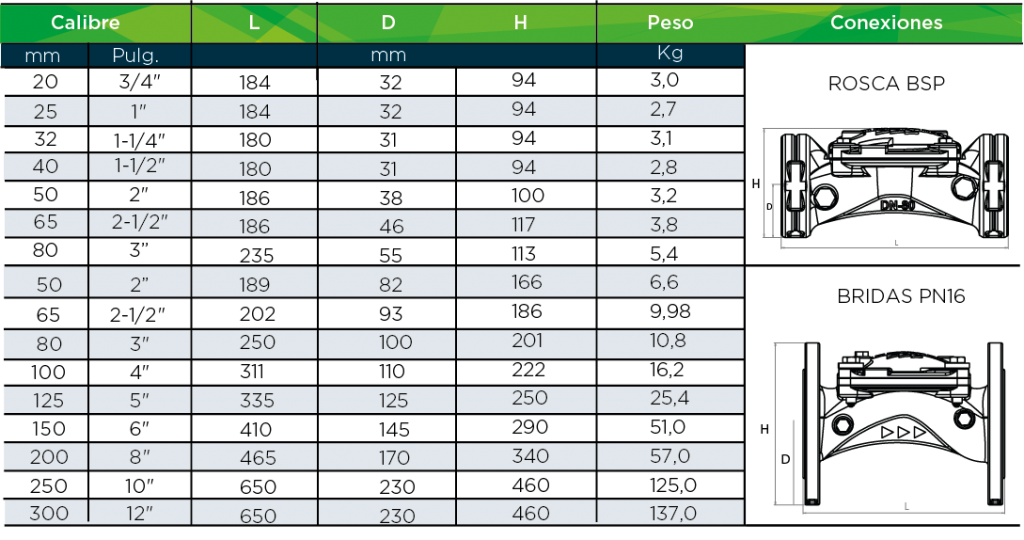

Leopard pressure sustaining valves are available from DN 20 to DN 300 diameter.

LEOPARD pressure sustaining hydraulic diaphragm valve. Used in installations where a specific pressure should be sustained.

Leopard pressure sustaining valves are available from DN 20 to DN 300 diameter.

Válvula hidráulica de membrana LEOPARD sostenedora de presión: Mantenimiento de una presión hidráulica mínima en instalaciones

La válvula hidráulica de membrana LEOPARD sostenedora de presión es una solución ideal para mantener una presión hidráulica mínima en instalaciones. Esta válvula de membrana funciona de manera efectiva al regular la presión hidráulica en la tubería y asegurar que se mantenga un mínimo de presión hidráulica en la línea principal, independientemente de la demanda de distribución.

Con la gama de válvulas LEOPARD sostenedora de presión, se pueden cubrir una amplia variedad de aplicaciones ya que están disponibles en tamaños desde DN 20 hasta DN 300. Su aprobación garantiza que la válvula cumpla con los estándares europeos de calidad y seguridad.

Applications

It is used in installations where it is desired to maintain a mínimum hydraulic pressure, such as:

The installation of this type of valves allows to maintain a minimum pressure upstream set by the user.

Functioning

The pressure sustaining valve is designed to maintain a minimum upstream pressure if the pressure is higher than the set value. Otherwise the valve will close until the upstream pressure is equal to or greater than the tare.

Turning the sustainer pilot screw clockwise you will reduce the intlet pressure. Turing the pilot anti-clockwise you will increase the outlet pressure.

1- Why does not the valve open?

There may be insufficient pressure at the inlet pressure valve, you should examine the insulation valves of the system upstream and downstream, if they are closed open to allow the passage of water and generate pressure.

Another reason may be that the solenoid is calcified, clean it and replace parts as necessary.

2- Why does not the valve regulate at the desired control point?

It may be caused by the pilot because it is not adjusted properly, check it by tightening and loosening the screwdriver to see if there is a pilot reaction, so you can adjust the pilot to the desired opening and closing speed.

Check if the upstream filter is clogged and causes insufficient pressure to reach the pilot to activate the valve at the desired control point.

3- Why does not the valve close?

It may be that the filter is clogged, to check it, disconnect the copper line from the lid to see if there is water flow in the inlet. In this case clean the filter mesh.

If the main valve membrane fails, it can also give this result, replace the membrane for repair.

Another reason may be that the solenoid is calcified, clean it and replace parts as necessary.

4- Why does the membrane leak water?

It is usually produced by the accumulation of dirt between the membrane and its closing support, closing the valve manually, if the problem persists open the valve to clean the area.