Created by Ana Valverde – Hidroconta

![]()

Choosing the wrong meter will mean that it counts too much water, or too little, or simply doesn’t count at all.

Mechanical and ultrasonic meters

Fortunately, in this case, choosing the right diameter only depends on the flow rate that you will be measuring, making this a simple task.

This figure is the meter’s constant flow rate or Q3.

Let’s remember the definition of the operating flow rates of water meters. The operating flow rates of a water meter are defined as follows:

- Q1, the minimum flow rate is the minimum value at which the meter operates without exceeding the maximum permissible error value (ɛ1).

- Q2, the transitional flow rate is the value between the constant or nominal flow rate and the minimum flow rate.

- Q3, the constant flow rate is the maximum flow rate within nominal operating conditions at which the meter is required to operate satisfactorily without exceeding the maximum permissible error value. Generally, at this flow rate, the manufacturer guarantees that the meter can operate continuously.

- Q4, the overload or maximum flow rate is the flow rate at which the meter should be able to operate without any damage for limited periods of time. In other words, exceptionally, at this level it can operate and maintain measurement errors below the maximum permissible error values, recovering its functionality when it subsequently returns to normal operating conditions.

The key to ensuring that the meter works correctly is to make sure that the maximum flow rate passing through the meter never exceeds Q3.

Also remember consider the minimum flow rate (Q1) of the supply network, below which meters are unable to provide accurate readings.

The flow rate of our hydraulic net should always be around Q3 and not above, and never below Q1.

If you choose a meter that is too large, you may lose accuracy as it may operate below Q1. Meters that continuously operate at the overload flow rate (Q4) have a shorter service live and less accuracy.

Choose a meter with a size that is suitable for the flow rate that you will be measuring.

The constant flow rate (Q3) of each meter is determined by each manufacturer, so choosing one could not be simpler. You only have to check the Q3 of each meter and make sure that the flow rate being measured does not exceed this (and it should also not be below Q1).

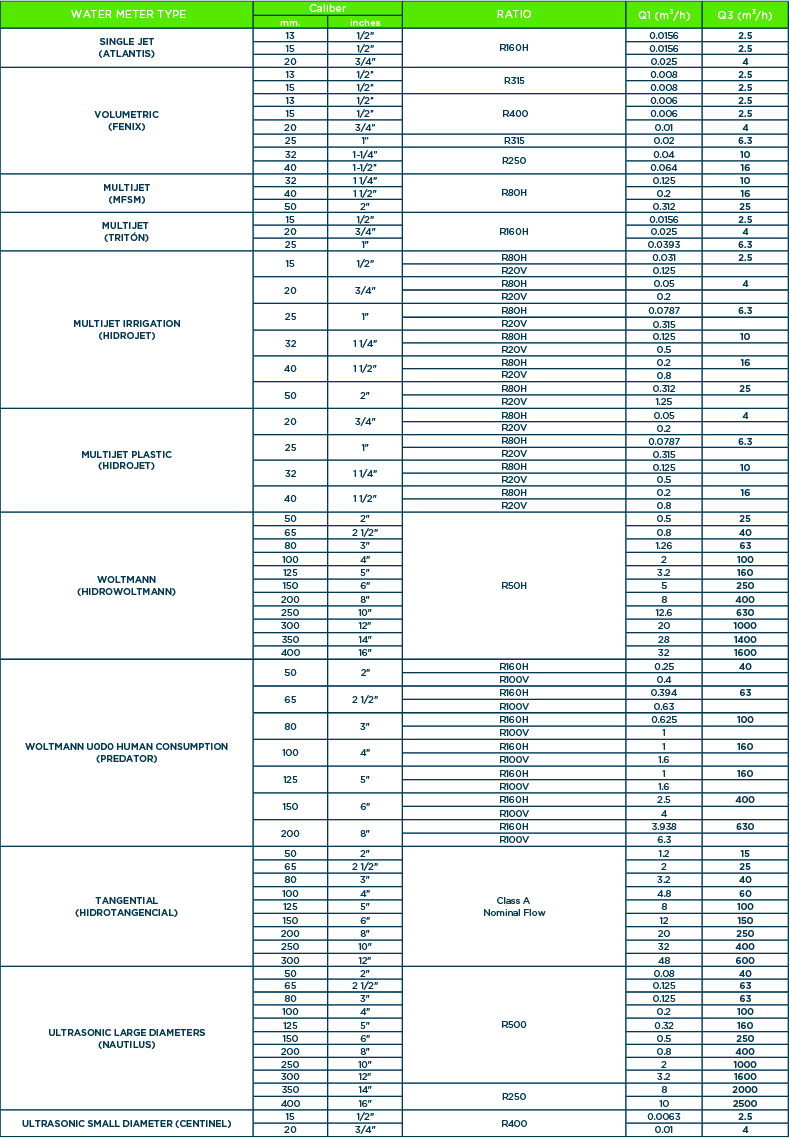

To help you, below there is a table of the nominal flow rates of an outstanding manufacturer (😉), to serve as a reference. You should always check with a professional before making the final decision.

Eleromagnetic flowmeters

Electromagnetic flowmeters work differently and, therefore, they are also sized differently.

In this case, if you pass a conductive fluid through the meter, where two powered coils produce a magnetic field, you close the circuit and the voltage will be proportional to the speed of the fluid. As we already know the cross-section of the measuring tube, we know the fluid’s flow rate.

So, to size an electromagnetic meter, you only need to know the speed of the fluid. The flow meter will operate effectively when the m/s flow rate is near to the optimum level specified by the manufacturer, and always above 0.5 m/s.

It is important to note that the tubes must always be full for these meters to measure correctly.

We normally install an electromagnetic meter of the same size as the tubes to avoid any load losses. However, for economic reasons, they can be smaller, as long as you bear in mind that this will lead to load losses.

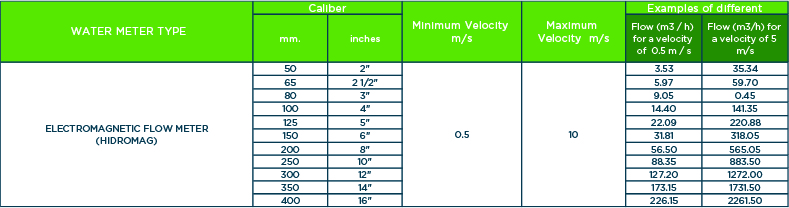

The manufacturer specifies the meters’ flow rates. This table is for reference purposes.

I hope that you have found this article useful.

As always, we recommend contacting a metering specialist for further advice.

Thanks a lot dearest colleagues for your support and help during this article writing.