LEOPARD hydraulic diaphragm valve with float. This valves control the reservoirs filling.

Leopard Float hydraulic valve

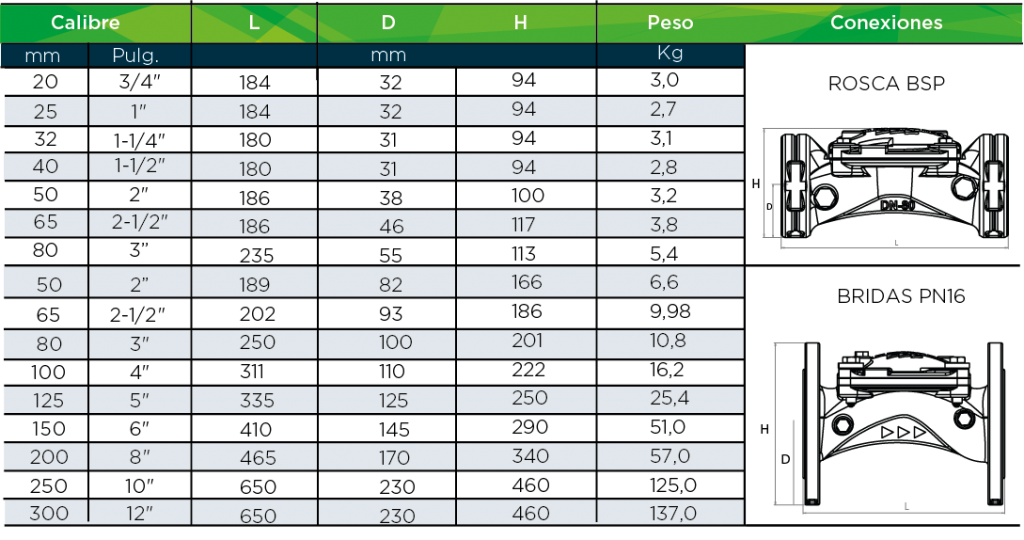

Leopard with float level valves are available from DN 20 to DN 300 diameter.

LEOPARD hydraulic diaphragm valve with float. This valves control the reservoirs filling.

Leopard with float level valves are available from DN 20 to DN 300 diameter.

Applications

Float valves are used in water tanks or regulation tanks. It is designed to fully open when the water level reaches a preselected low and closes tightly when it reaches the selected high level.

Functioning

When the water level in the tank reaches its maximum point, the buoy pilot closes the water passage, accumulating the water pressure in the valve chamber and closing it. When the water level in the tank drops due to consumption, the buoy pilot also descends, opening the water passage and draining the chamber, which opens the hydraulic valve.

In the case of the 1-level hydraulic float valve, the opening and closing of the valve is carried out through the float equipment.

In the 2-level float valve, the opening and closing set of the valve is carried out through the pilot, 3-way manual valve and 2-level float equipment. In relation to the operation of the 2-level hydraulic float valve, the valve opens only when the level of the water sheet reaches the lower buoy, sending the corresponding order to the pilot. When the water level reaches the upper buoy again, it sends an order to the pilot and the valve is closed.

1- Why does not the valve open?

There may be insufficient pressure at the inlet pressure valve, you should examine the insulation valves of the system upstream and downstream, if they are closed open to allow the passage of water and generate pressure.

Another reason may be that the solenoid is calcified, clean it and replace parts as necessary.

2- Why does not the valve regulate at the desired control point?

It may be caused by the pilot because it is not adjusted properly, check it by tightening and loosening the screwdriver to see if there is a pilot reaction, so you can adjust the pilot to the desired opening and closing speed.

Check if the upstream filter is clogged and causes insufficient pressure to reach the pilot to activate the valve at the desired control point.

3- Why does not the valve close?

It may be that the filter is clogged, to check it, disconnect the copper line from the lid to see if there is water flow in the inlet. In this case clean the filter mesh.

If the main valve membrane fails, it can also give this result, replace the membrane for repair.

Another reason may be that the solenoid is calcified, clean it and replace parts as necessary.

4- Why does the membrane leak water?

It is usually produced by the accumulation of dirt between the membrane and its closing support, closing the valve manually, if the problem persists open the valve to clean the area.